Precision Weight Weighing and Packaging Machine

본문

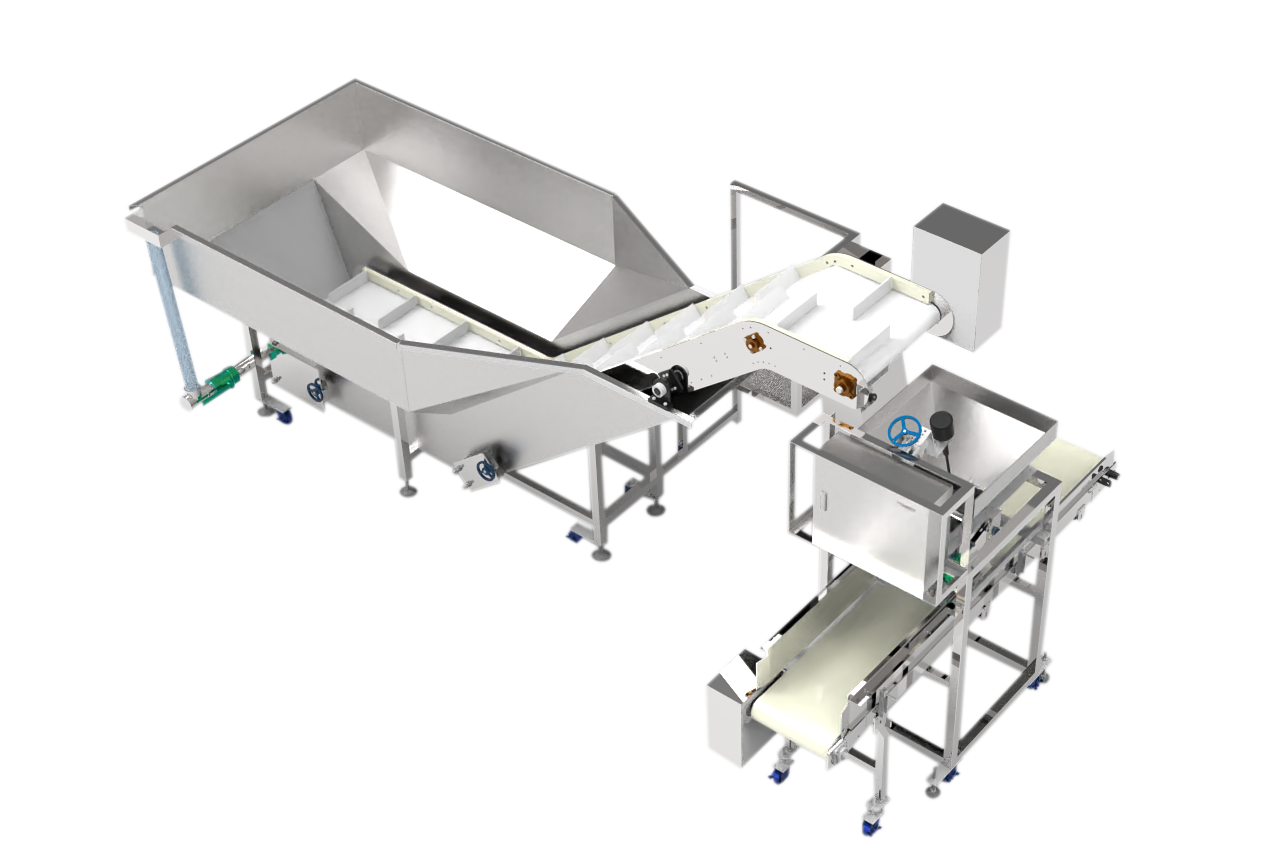

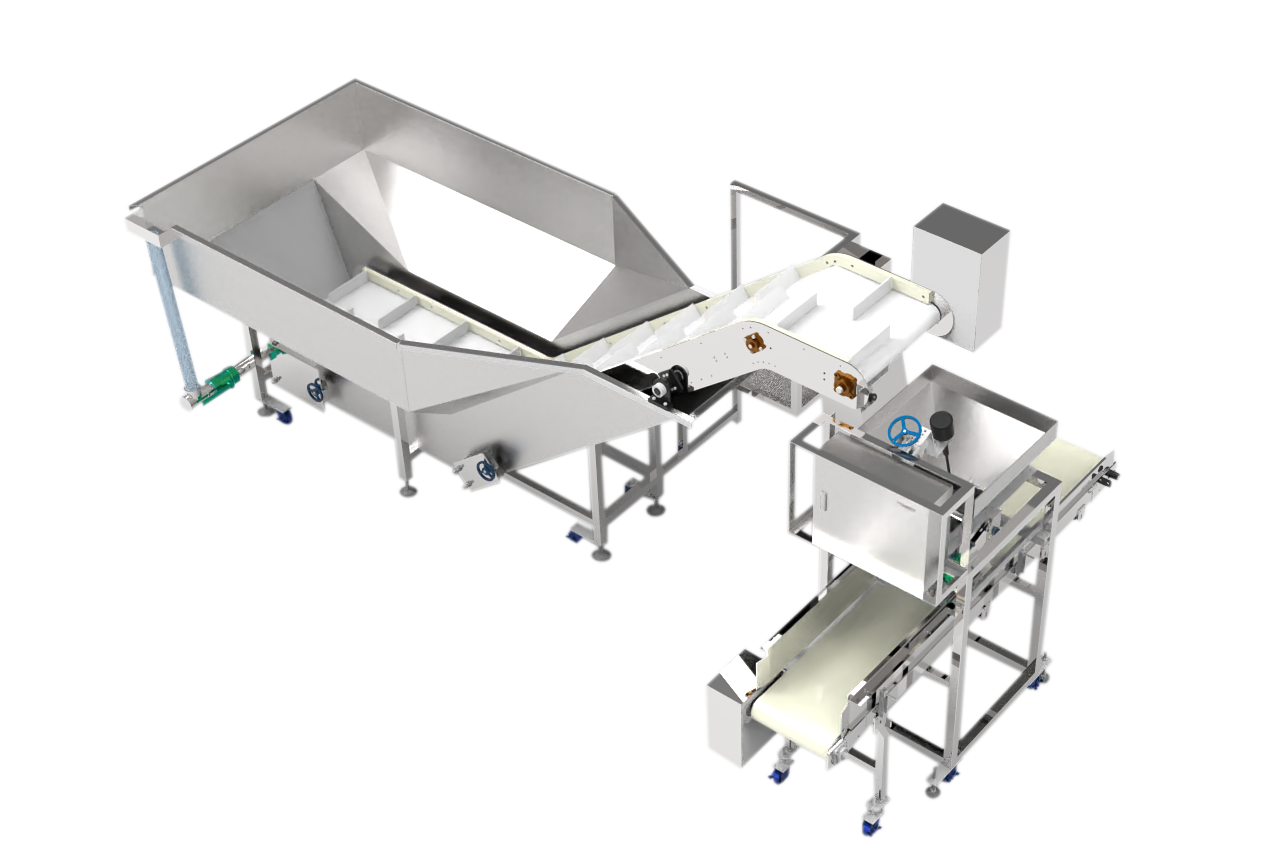

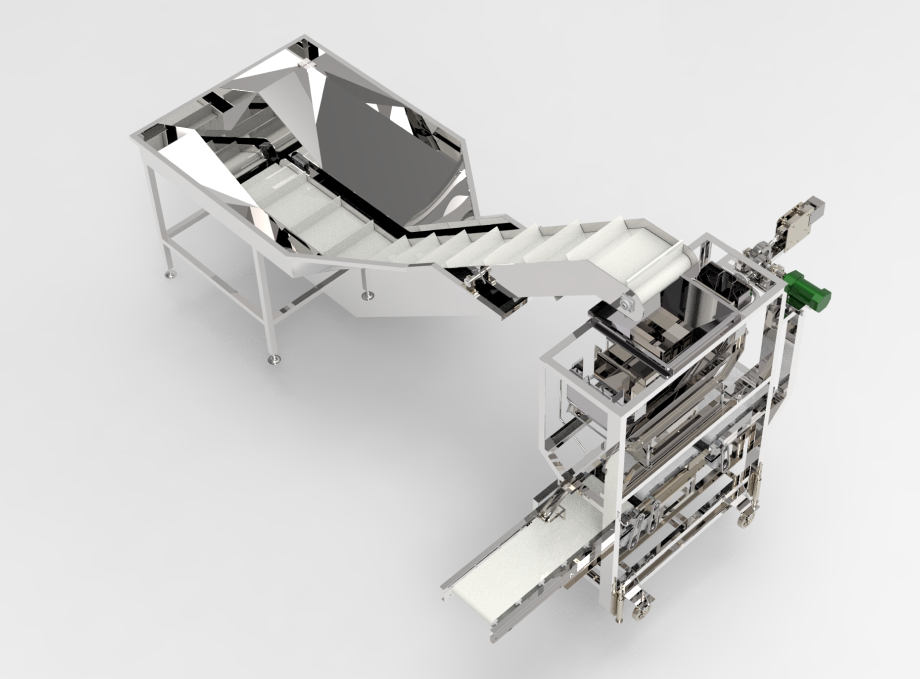

Wet Hopper and Inclined Conveyor

Product Features

- Sorted mackerel is transferred via the conveyor to the intermediate hopper, where it is temporarily stored and then supplied to the precision weighing unit by the hopper lift conveyor.

- It operates according to signals from the precision weighing unit, and the weighing speed can be adjusted via an inverter.

- Large doors are attached to the left and right sides of the bottom of the hopper, allowing easy cleaning and maintenance after operation.

Product Specifications

DIMENSION : L×W×H ㎜

CAPACITY

POWER

4200L x 1700W x 2350H

1.3Ton

3P x 380V x 1.5KW

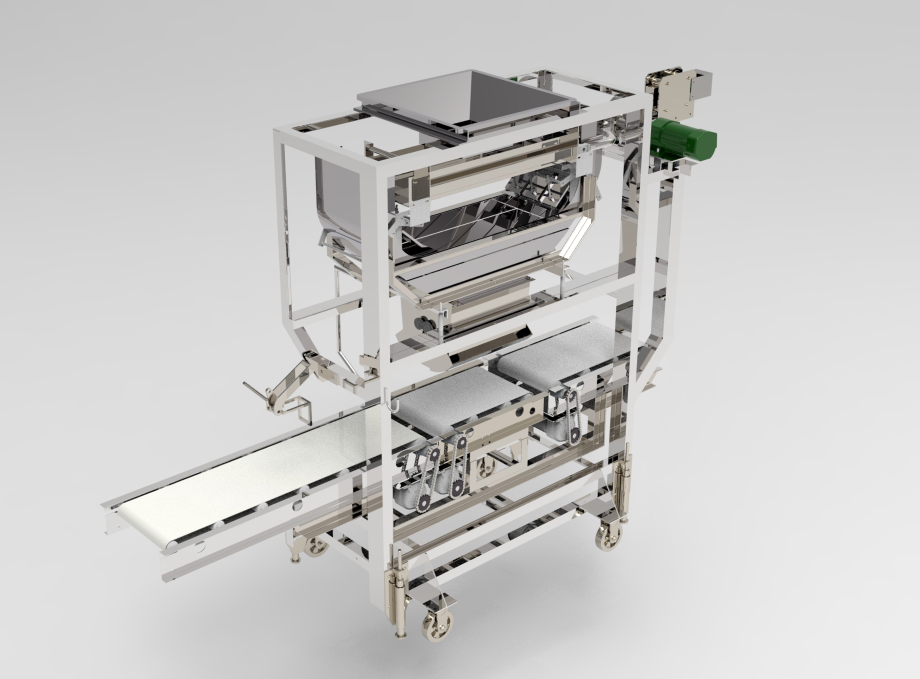

Precision Weighting Unit

Product Features

- Mackerel delivered by the hopper elevating

conveyor is dropped into a hopper and weighed by

four load cells. The fish are then released into a box

below once the preset weight is reached.

- The system uses electronic weighing instead of

volume-based measurement, resulting in minimal

weight deviation and high-speed operation.

- Target weight can be easily adjusted or changed

using a touchscreen interface.

- The box below follows automated steps—

box supply → box stop → fish insertion →

box discharge—triggered by signals from the

precision weighing unit.

Product Specifications

DIMENSION : L×W×H ㎜

POWER

MEASURING SCOPE

MEASURING SPEED

MEASURING DEVIATION

1700L x 800W x 1845H (Excluding Hopper Lift Conveyor)

3P x 380V x 0.75KW

5~30kg

15~20 box/min (Based on 20kg)

±150g (Based on Small Fish / Feed Use)

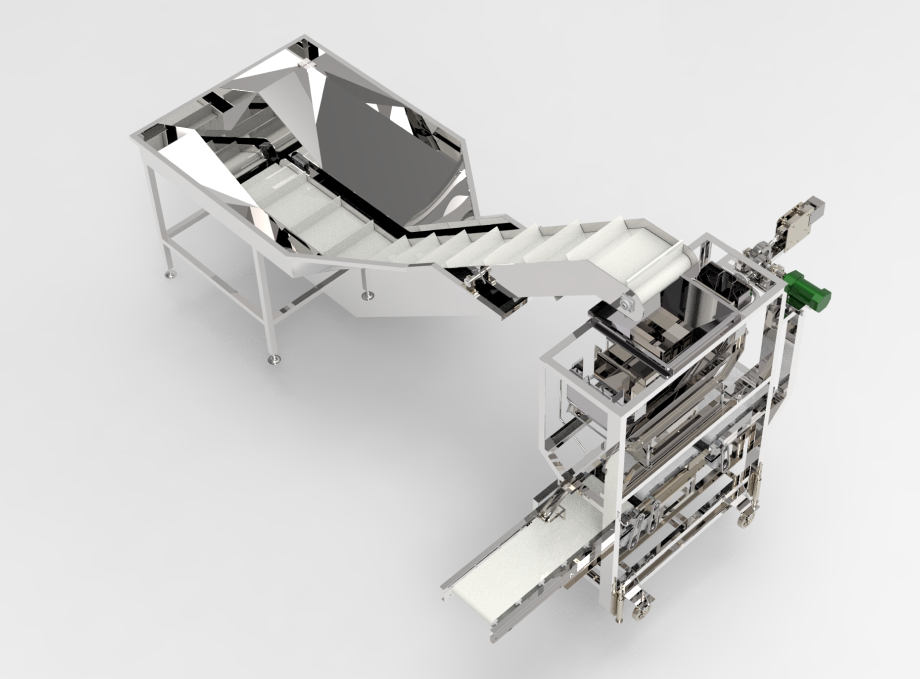

Automatic Sorting Precision

Weighting Unit (Double Type)

Product Features

- Mackerel delivered from the hopper elevating conveyor is

transferred to a supply conveyor, which alternately feeds the fish

onto two weighing conveyors positioned on the left and right.

- The dual load cell setup allows for alternating operation, increasing

weighing efficiency by 1.5 times.

- While one conveyor completes weighing and discharges mackerel

into the lower box, the other continues weighing, thereby enabling

continuous high-speed operation.

- The weighing conveyor aligns the head and tail of the mackerel ,

allowing operators to neatly pack the fish into boxes with minimal

manual effort.

Product Specifications

DIMENSION : L×W×H ㎜

POWER

MEASURING SCOPE

MEASURING SPEED

MEASURING DEVIATION

4300L x 2160W x 1930H (Excluding Hopper Lift Conveyor)

3P x 380V x 2KW

5~30kg

10~15 box/min (Based on 20kg)

±400g (Based on 300g Mackerel)

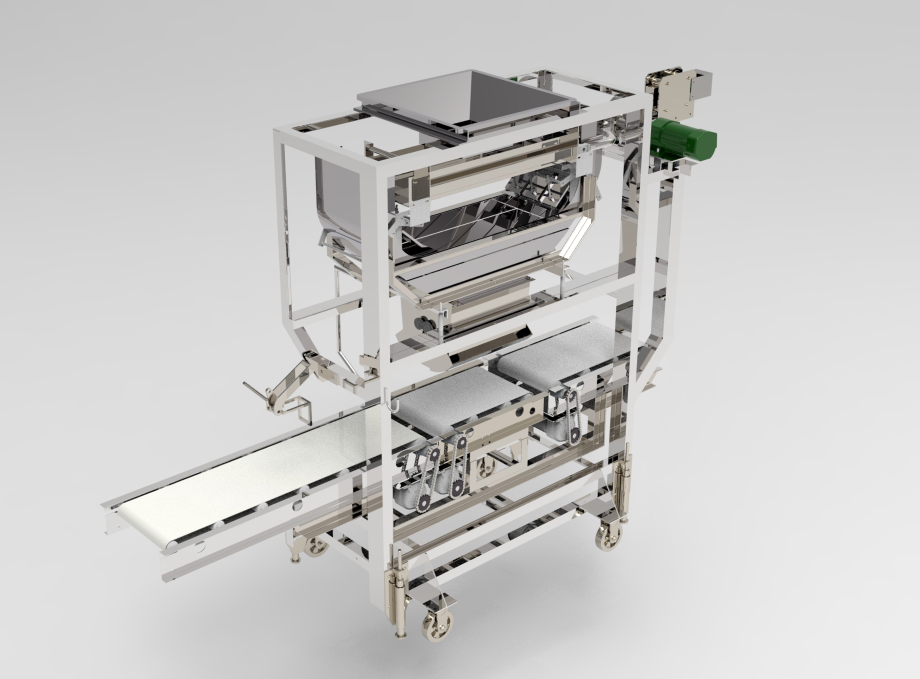

Automatic Sorting Precision

Weighting Unit

Product Features

- Mackerel transferred from the hopper lift conveyor is dropped into the weighing hopper, where the swing alignment device arranges the head and tail, and the load cell measures the weight before releasing it into the box below.

- Since the weight is measured by a load cell, the margin of error is minimal.

- he target weight can be easily adjusted via the touchscreen..

Product Specifications

DIMENSION : L×W×H ㎜

POWER

MEASURING SCOPE

MEASURING SPEED

MEASURING DEVIATION

3273L x 1117W x 2187H (Excluding Hopper Lift Conveyor)

3P x 380V x 0.4KW

5~30kg

10~15 box/min (Based on 20kg)

±400g (Based on 320g Mackerel)

- PrevRoller-Type Sorter 25.05.07

- NextIce and Cooling Water Metering System 25.05.07

댓글목록

등록된 댓글이 없습니다.

회원로그인

회원가입

-

Precision Weight Weighing and Packaging Machine

- Sorted mackerel is transferred via the conveyor to the intermediate hopper, where it is temporarily stored and then supplied to the precision weighing unit by the hopper lift conveyor.

- It operates according to signals from the precision weighing unit, and the weighing speed can be adjusted via an inverter.

- Large doors are attached to the left and right sides of the bottom of the hopper, allowing easy cleaning and maintenance after operation.

- Mackerel delivered by the hopper elevating conveyor is dropped into a hopper and weighed by four load cells. The fish are then released into a box below once the preset weight is reached.

- The system uses electronic weighing instead of volume-based measurement, resulting in minimal weight deviation and high-speed operation.

- Target weight can be easily adjusted or changed using a touchscreen interface.

- The box below follows automated steps— box supply → box stop → fish insertion → box discharge—triggered by signals from the precision weighing unit.

- Mackerel delivered from the hopper elevating conveyor is transferred to a supply conveyor, which alternately feeds the fish onto two weighing conveyors positioned on the left and right.

- The dual load cell setup allows for alternating operation, increasing weighing efficiency by 1.5 times.

- While one conveyor completes weighing and discharges mackerel into the lower box, the other continues weighing, thereby enabling continuous high-speed operation.

- The weighing conveyor aligns the head and tail of the mackerel , allowing operators to neatly pack the fish into boxes with minimal manual effort.

- Mackerel transferred from the hopper lift conveyor is dropped into the weighing hopper, where the swing alignment device arranges the head and tail, and the load cell measures the weight before releasing it into the box below.

- Since the weight is measured by a load cell, the margin of error is minimal.

- he target weight can be easily adjusted via the touchscreen..

- PrevRoller-Type Sorter 25.05.07

- NextIce and Cooling Water Metering System 25.05.07

본문

Wet Hopper and Inclined Conveyor

Product Features

Product Specifications

| DIMENSION : L×W×H ㎜ | CAPACITY | POWER |

|---|---|---|

| 4200L x 1700W x 2350H | 1.3Ton | 3P x 380V x 1.5KW |

Precision Weighting Unit

Product Features

Product Specifications

| DIMENSION : L×W×H ㎜ | POWER | MEASURING SCOPE | MEASURING SPEED | MEASURING DEVIATION |

|---|---|---|---|---|

| 1700L x 800W x 1845H (Excluding Hopper Lift Conveyor) | 3P x 380V x 0.75KW | 5~30kg | 15~20 box/min (Based on 20kg) | ±150g (Based on Small Fish / Feed Use) |

Automatic Sorting Precision Weighting Unit (Double Type)

Product Features

Product Specifications

| DIMENSION : L×W×H ㎜ | POWER | MEASURING SCOPE | MEASURING SPEED | MEASURING DEVIATION |

|---|---|---|---|---|

| 4300L x 2160W x 1930H (Excluding Hopper Lift Conveyor) | 3P x 380V x 2KW | 5~30kg | 10~15 box/min (Based on 20kg) | ±400g (Based on 300g Mackerel) |

Automatic Sorting Precision Weighting Unit

Product Features

Product Specifications

| DIMENSION : L×W×H ㎜ | POWER | MEASURING SCOPE | MEASURING SPEED | MEASURING DEVIATION |

|---|---|---|---|---|

| 3273L x 1117W x 2187H (Excluding Hopper Lift Conveyor) | 3P x 380V x 0.4KW | 5~30kg | 10~15 box/min (Based on 20kg) | ±400g (Based on 320g Mackerel) |

댓글목록

등록된 댓글이 없습니다.